Research Article - (2024) Volume 1, Issue 1

Selection of the Optimum Material for Prefabricated Structures by AHP

Received Date: Oct 07, 2024 / Accepted Date: Oct 18, 2024 / Published Date: Nov 08, 2024

Copyright: ©�??�?©2024 ?afak Kocakalay, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Citation: Erk?lavuz, N., Kocakalay, S. (2024). Selection of the Optimum Material for Prefabricated Structures by AHP. Ann Civ Eng Manag, 1(1), 01-11.

Abstract

The construction sector is known as the least digitalized sector after the hunting and agriculture sectors among 22 sectors. The beginning of the industrialization process in the construction sector has entered our lives with prefabrication. Prefabricated systems accelerate the construction process and enable faster production. The emerging prefabricated construction technology contributes to faster, easier, and more cost-effective construction of buildings. Today, interest and demand for prefabricated structures have increased. Multi-criteria decision-making (MCDM) is a method that helps to determine the best choice by evaluating various criteria together. The use of AHP (Analytic Hierarchy Process), which is one of the MCDM methods, is frequently preferred in solving multi-criteria decision-making problems. Within the scope of the article; it is aimed to be an interdisciplinary study by evaluating prefabricated structures, which are accepted as the beginning of industrialization in the construction sector, and MCDM methods together. In this article, alternative materials used in prefabricated building systems and sub-criteria affecting the materials were analyzed. AHP was used as the methodology in the study and the selection of the optimum material for prefabricated structures was carried out. In order to apply the method, appropriate criteria were determined and then the criteria were scored by experts in the field. Then, the values of 3 types of materials (alternatives) for prefabricated buildings were determined. After the AHP method was applied, it was found that the optimum material among the alternatives was steel.

Introduction

The origin of the word prefabricated is based on French. In English, it means prefabricated, which is formed by the combination of the words pre and fabricated. As can be understood from the meaning of the word, the advantages of prefabricated products are due to the fact that the building elements are prefabricated in the factory environment. Thanks to prefabricated systems, many building elements to be built can be prefabricated. The construction sector can be immediately affected by many factors such as wars, natural disasters, and increasing population. As a result of these factors, with the increase in the need for shelter, prefabricated structures have shown great development and gained an industrial dimension. In order to meet the housing demand, developed countries have turned to unique and innovative solutions such as prefabricated buildings as well as traditional construction methods.

In the construction sector, various industrialization studies and new technologies are being developed in order to accelerate production and reduce costs. In this context, the prefabrication method plays an important role in faster, high quality, and economical production of structural systems. The production of prefabricated building elements is carried out with various quality control activities in the factory environment. Prefabricated elements that pass these quality control steps are produced under much better conditions than the conditions in the field. Prefabrication accelerates the building production process and enables the desired speed to be reached. Throughout history, people have had to make various choices both in their individual lives and as a society. Similarly, in daily life, we tend to prefer options that minimize and minimize costs and maximize benefits in the decision-making process.

The decision-making process takes place by considering certain criteria (criteria) and making a choice among available alternatives (options). These criteria are usually of varying degrees of importance and each alternative is evaluated differently for each criterion. Multi-criteria decision-making is a method that brings together experts from various disciplines to facilitate the process of analyzing problems and choosing between alternative solutions for decision-makers. This approach enables the integration of knowledge from different fields and various disciplines such as engineering, mathematics, statistics, economics, social sciences, management, and business. It is possible to define MCDM problems as problems in which more than one criterion is optimized and the best alternative is selected from a set of possible solutions [1].

Methods

Multi-criteria decision-making (MCDM) methods, which have been developed to make the most appropriate choice among multiple alternatives in complex decision processes, is a method that facilitates the process of problem analysis and selection among alternative solutions for decision-makers by bringing together various experts from various disciplines. This approach enables the integration of knowledge from different fields and various disciplines such as engineering, mathematics, statistics, economics, social sciences, management, and business. It has an important place, especially in disciplines such as engineering, construction, and material sciences. These techniques offer effective solutions in decision problems where various criteria need to be evaluated. The Analytic Hierarchy Process (AHP), which is one of the most prominent among the MCDM methods, provides a hierarchical structure for decision-makers to determine the priorities among the criteria and to make the best decision among the alternatives. AHP, introduced by Saaty, makes it possible to select the most appropriate alternative by analyzing the decision process step by step and making comparisons between alternatives.

The prefabricated building sector provides benefits such as accelerating the construction process, providing cost advantages, and superior quality management. However, the success of these structures depends on the correct selection of the materials. Material selection should be made according to many different criteria such as longevity of prefabricated structures, durability, cost-effectiveness, and environmental impacts. While conducting the literature review, prefabricated structures, materials for prefabricated structures, MCDM methods, and AHP methods were investigated and the studies conducted in this context were analyzed. There are a large number of studies in which the use of MCDM methods is used and recommended in selection problems in many different fields and these methods contribute to decision processes. In the research conducted by Zavadskas et al., in 2014, it was shown that AHP offers significant advantages in the process of material selection in the construction industry [2]. Within the scope of this article, the AHP method will be used for the selection of materials for prefabricated structures and the criteria determined will be taken as a basis. It has been observed that AHP is widely preferred in such decision problems in the literature and it will be considered as a suitable method for optimum material selection in this study.

1. Prefabricated Buildings in Construction Sector

Prefabrication is the process of pre-preparation of building elements in the factory environment, in workshops or industrial plants established on construction sites. It refers to the process of assembling or pre-assembling completed or semi-completed building elements by producing them in the factory according to predetermined standards and transporting them to the construction site. Prefabricated structure; It is the process of creating a building with the principle of assembling the building elements prepared in accordance with the project one by one in the factory environment by assembling them in the construction area. Prefabricated element is used to define the elements that require processing in the factory environment due to the production of a large number of parts.

The general purpose of prefabricated elements is to minimize the work to be done when they are brought to the assembly site, to optimize the work process, to keep the quality of the element under control, and to ensure standardization [3]. The structures produced by this method have higher quality standards compared to traditional construction methods applied in construction site environments.

In the production of prefabricated building elements, the world technology trend is gradually moving towards computerized controlled systems that reduce the need for manpower. After the projects are prepared in a computer environment, stages such as preparation and stocking are also automated with the spread of automation in production processes. In the construction sector, prefabricated structures initially developed primarily in the industrial sector. One of the important factors of the development in the industrial sector is due to the short production times. The desire of entrepreneurs for fast production and investment transformation has contributed to the widespread use of prefabrication, especially for industrial buildings. However, prefabrication in the residential sector is not as common as in industrial buildings. Nevertheless, in many industrial and residential buildings, prefabrication systems are used as both structural elements and carrier systems. While the human element is of great importance in construction with traditional materials and methods, in factory production processes, minimizing human errors, shortening production time, reducing costs, reducing waste and increasing quality becomes a priority.

Advantages of Prefabricated Buildings

• Prefabricated elements can be manufactured in a short time.

• Material-related waste is minimized.

• Labor costs are lower than in traditional construction.

• The construction process is not affected by the weather.

• It provides high-quality control. The margin of error is low.

• It is more durable and long-lasting than traditional structures.

• It provides ease of assembly and transport due to its easy disassembly and assembly.

• Prefabricated building elements are more environmentally friendly as most of them consist of recyclable materials.

Disadvantages of Prefabricated Buildings

• The joints of prefabricated structures must be carefully designed and implemented.

• Due to the discontinuity in prefabricated structures with large spans, it is difficult to predict their behavior during an earthquake.

• Design errors are difficult to correct on-site. The dimensions of prefabricated elements cannot be easily changed on-site.

• The application of prefabricated structures for small openings increases the cost.

• The handling and transport of prefabricated building elements of large dimensions increases both cost and logistics costs.

Classification of Prefabricated Structures in Terms of Material

Carcass is the name given to the building system that forms the basic skeleton of buildings. Typically, they consist of columns and beams. They form the carrier system of buildings. Structures transfer the load to the ground by means of columns and beams through their structure. The nomenclature of carcass structures varies according to the material used in the structure. Prefabricated systems are classified according to different criteria. These criteria include factors such as the weight of the material, classification according to the building system, and the type of material. In addition to the main classifications, they can also be divided into more detailed subcategories. In this article, prefabricated buildings were classified according to the material, and these material alternatives were analyzed.

The materials used in the prefabricated systems are divided into three types as;

• Steel

• Concrete

• Wooden

Steel Prefabricated Structures

Steel is an alloy of iron obtained by shaping iron by different methods. Iron must be pressed or rolled in order to be shaped. The main components of the steel material are iron and carbon. While carbon increases the hardness of steel, it reduces the elongation at break and tensile strength. For this reason, the carbon content of hot-rolled steel alloys generally varies between 0.16 and 0.20 percent [4]. S 235, S 275, and S 355 steels stand out among the materials frequently used in the construction sector. These steel types are named according to the durability of the material, ie the strength value it has. Steel materials used in construction can be found in various sections and shapes. The most commonly used section types consist of I, L, and T-shaped profiles. Under normal conditions, the life span of steel prefabricated structures generally varies between approximately 40 and 70 years.

Advantages of Steel Material

• It is a material that provides resistance against earthquake.

• Steel is a completely recyclable material.

• Structural steel is a sustainable building material.

• The self-weight of the structures constructed with steel material is quite light.

• Steel material allows even millimetric dimensions to be produced at the most precise level in the factory environment.

• By providing ease of assembly thanks to its bolted joint feature; it accelerates the construction process and provides convenience in terms of labor.

Disadvantages of Steel Material

• Steel material is more expensive compared to wood and concrete materials.

• With the increase in temperature, the strength and modulus of elasticity of structural steel decreases rapidly. Since structural steel is a good heat conductor, the heated part weakens and loses its strength.

• Contact of steel material with water or chemicals can lead to corrosion.

• Steel structures require periodic maintenance.

• Insulation costs are high in steel structures.

Concrete Prefabricated Structures

Prefabricated concrete structures are building systems formed by combining concrete elements previously produced in factories or workshops. These structures constitute a construction method in which the concrete elements produced in special moulds in the factory are then transported to the construction site and assembled. Reinforced concrete structures have become the most widely preferred building material in the 20th and early 21st centuries thanks to their load-bearing capacity, durability, and ease of production [5]. One of the building systems where reinforced concrete is used is prefabricated concrete structures. Prefabricated concrete building systems are increasingly preferred due to their advantages such as shorter construction time, less labour requirement and less work in the field [6]. Prefabricated concrete structures have a heterogeneous structure formed by the combination of materials such as cement, sand, aggregate, and water. The quality of concrete depends on the amount of materials in it, the additives used, and the curing process. With additives, concrete can be freed from its brittle characteristic offers various usage possibilities, and can be shaped as desired. Concrete can be easily obtained, but its application requires labour. It can be used in different areas such as frame systems, panels, modules, and prefabricated production is more efficient than traditional methods. Production in a factory environment ensures that concrete is not affected by weather conditions and makes it possible to obtain the same quality product from the same mould [7].

Advantages of Concrete Material

• Concrete is a building material with high resistance to fire.

• Concrete is a building material that is generally economical and cost-effective.

• Concrete prefabricated structures have high load carrying capacity.

• Strength is high in concrete prefabricated structures.

• Concrete building material is resistant to external influences. It does not show deformation over time.

• Concrete provides good sound and heat insulation.

Disadvantages of Concrete Material

• Reinforced concrete prefabricated structures generally use heavier elements compared to other building materials.

• After the concrete has been poured into molds for forming, it has limited flexibility if it is desired to modify the shape of the material.

• Concrete needs a certain period of time to dry completely and then harden and become durable.

• On large concrete surfaces, cracking may occur during drying.

• Concrete is a less flexible material compared to other building materials.

Wooden Prefabricated Structures

Prefabricated wood materials have an important role in the construction sector thanks to its natural structure. Its easy processing allows it to be shaped in accordance with different usage areas. When designed and built correctly, it can maintain its durability for many years. Especially in countries with large forest resources, wooden building elements are widely preferred for one or two story houses. The possibilities provided by prefabrication technology enable mass production of these materials at high quality and standards, making significant contributions to construction processes.

Advantages of Wood Material

• The weight of the structure is light in wooden prefabrication.

• Due to its lightweight, transport and assembly processes are easier.

• It is an effective material to significantly reduces basic costs.

• Wood is a material that is easy to process and shape.

• It creates a minimum level of waste material with its wooden material.

• Wood is a natural insulating material and provides good thermal insulation.

Disadvantages of Wood Material

• Wood building material is flammable.

• Insect species and termites can damage wood building material.

• Wood is a building material sensitive to humidity and temperature changes.

• Wood is a building material prone to rot in damp and humid environments.

• Wooden structures require regular maintenance and protective measures.

• The strength of wood material is lower than other building materials.

Multi-Criteria Decision Making

Multi-criteria decision-making (MCDM) methods contribute to the evaluation of quantitative and qualitative criteria in situations where more than one criterion exists. These techniques are effective methods that are frequently used to solve complex problems. Multi-criteria decision-making offers solutions that provide compromise through the integration of different strategies and techniques. These methods have been developed to help decision-makers manage their decision-making processes more effectively. In general, the multi-criteria decision-making model provides a systematic approach to identifying the most appropriate option, focusing on the evaluation and ranking of available alternatives. The first step in the multi-criteria decision-making process is to clearly define the problem and objectives. In line with the defined objectives, suitable alternatives are identified. Afterward, it is necessary to correctly determine the criteria by which these alternatives will be evaluated. It is important that the criteria are comprehensive, i.e. that they enable the alternatives to be fully evaluated. Because the criteria directly affect the solution of the problem.

Then, the necessary data are collected for each alternative and these data are used in the construction of the decision matrix that enables the alternatives to be organized according to the criteria. Since the determination of criterion weights directly affects the ranking of alternatives, it is important to determine them correctly using subjective, objective, or hybrid methods. After this stage, the alternatives are evaluated and ranked on the basis of all criteria and the optimal alternative is identified and recommended. Finally, the proposed optimal alternative is evaluated by the decision maker and the final decision is made [8]. Multi-criteria decision-making is a field that is a branch of decision-making studies that can be considered within decision-making studies. It can also be considered as a sub-branch of operations research that covers decision problems with many criteria [9]. Analytical Hierarchy Process (AHP), Analytical Network Process (ANP), TOPSIS, PROMETHEE, and ELECTRE methods are the most preferred ones in the literature. Within the scope of the article, AHP was used to solve the problem.

Analytic Hierarchy Process (AHP)

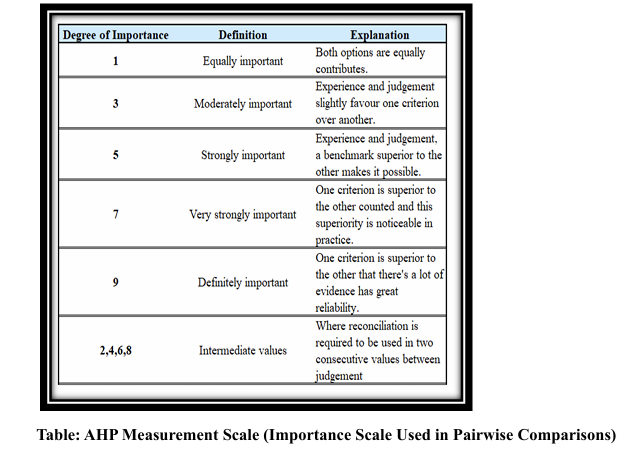

It was developed in 1977 by Thomas L. Saaty. AHP is a decision-making method based on creating criteria and alternatives and evaluating them in a one-to-one manner in order to realize the determined objective. It is a method that determines the objectives (sub-objectives, if any), basic criteria, and alternatives, defines them in a hierarchical order, especially the objectives, and reaches a conclusion by comparing the criteria and alternatives with each other. Weights are calculated by comparing the main and sub-criteria according to the 1-9 scale developed by Saaty. With these importance weights, the performance of the alternatives is evaluated. It is an approach that has many advantages compared to other methods in solving complex problems, in situations involving a large number of alternatives and criteria. The AHP method is a technique that is easily understood and easy to apply by decision-makers. This approach is a decision-making method that helps to determine and rank the weight scores of criteria and sub-criteria relative to each other, based on pairwise comparison of criteria and sub-criteria to achieve the set objectives. It is frequently preferred by researchers in different fields such as engineering, technology, manufacturing, production, and social sciences [10].

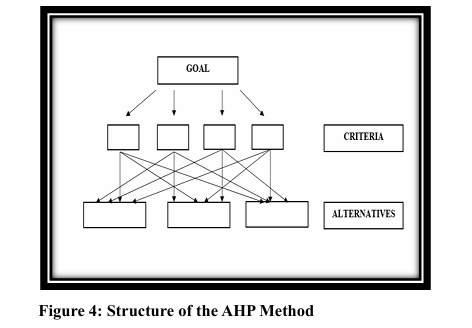

AHP first divides a problem into smaller parts and then brings the solutions of these sub-problems together. Organizing emotions, thoughts, decisions and perceptions in a structure that affects the decision facilitates decision-making. Judgments are also structured from a general to a more specific and controllable situation [11]. In the AHP method, a problem is addressed by examining the relationships between the main objective, criteria, sub-criteria, and alternatives through a hierarchical structure. Once the hierarchical structure is completed, the prioritization process begins. One of the most important features of this approach is that both objective and subjective views can be included in the decision-making process. AHP brings together the knowledge, experience, personal opinions, and intuitions of experts in the field in a logical way. In this way, individuals have the opportunity to make more informed choices by better understanding their own decision-making processes without being forced into a particular decision-making method.

The main problem in the decision-making process is to determine the most appropriate one among the options evaluated according to conflicting criteria. Most decision-making methods developed for this purpose include only quantitative criteria. However, in real life, the decision-making process is significantly influenced by semi-quantitative or qualitative criteria. What distinguishes AHP from other multi-criteria decision-making methods is the fact that quantitative and qualitative decision variables are evaluated together. Thanks to the advantage of the ease of application of the method, the interest and interest in this technique has increased considerably [12]. Instead of requiring people to make decisions in a certain way, AHP allows them to recognize their own decision making mechanisms by considering their observations in different psychological and sociological situations and thus aims to make better decisions [13]. In AHP, the problem is modeled by a hierarchical structure of relationships between the main objective, criteria, sub-criteria, and alternatives. Once the problem is hierarchically structured, this is followed by a prioritization process. One of the most important features of this approach is its ability to incorporate both objective and subjective considerations into the decision-making process.

There has been considerable debate among analysts and researchers, who are experts in the field of MCDM methods, about the advantages and disadvantages of AHP. Some information about the strengths and weaknesses of the AHP is given below. Strengths of the Analytic Hierarchy Process

• It creates a hierarchical structure by dividing problems into objectives, criteria, sub-criteria and alternatives.

• It offers decision-makers convenience and the ability to control inconsistencies.

• Pairwise comparisons by experts ensure that both subjective and objective evaluation criteria are considered.

• The AHP method provides a useful mechanism in the evaluation process by checking the consistency of alternatives and criteria and thus contributes to reducing the personal judgments of decision makers about alternatives.

• Thanks to weighting and ranking techniques, it has the ability to easily solve problems that are difficult or complex to model with traditional methods.

• It builds consensus by calculating the geometric mean of each pairwise comparison made by the experts, thus facilitating group decision-making.

Weaknesses of the Analytic Hierarchy Process

• Adding similar or identical options to the set of alternatives can lead to inconsistencies in the ranking.

• The use of a 1-9 scale is sometimes unrealistic in real-life problems. When making pairwise comparisons, decision-makers may f ind it difficult to distinguish between criteria.

• Decision problems are decomposed into subsystems that require a large number of pairwise comparisons between criteria. However, the disadvantage of this approach is that the number of pairwise comparisons is large and therefore the solution takes a long time.

Stages of the Analytic Hierarchy Process

The Analytic Hierarchy Process (AHP) is a systematic method that organizes the steps of decision-making. This process starts with defining the problem and clarifying the objective. Then, appropriate decision criteria and sub-criteria, if any, are selected in line with the determined objective. After this stage, a set of alternatives for selection is created and the hierarchical structure of the problem is established. At each level of the hierarchy, pairwise comparisons are made between the criteria and sub-criteria, and matrices are prepared based on these comparisons, followed by normalization of the matrices. The matrices and eigenvectors obtained after normalization help to determine the importance of each criterion. Then, for each criterion and sub-criteria, pairwise comparisons are made between alternatives to obtain importance score scores. After the consistency ratios of the pairwise comparison matrices are calculated, the alternatives are ranked according to their importance scores, and the alternative with the highest score is selected. If necessary, sensitivity analyses are also performed at the end of the process.

The upper limit is considered to be 9 on the AHP Measurement Scale. The reasons for this situation are as follows:

• Saaty's method gives the best results for n<10 criteria, especially for 7 criteria. In other words, when solving multi-criteria decision making problems with AHP, significant inconsistencies may occur in the results when more than 9 criteria are used.

• This can lead to greater inconsistencies when the elements of a matrix consist of very large numbers.

Results

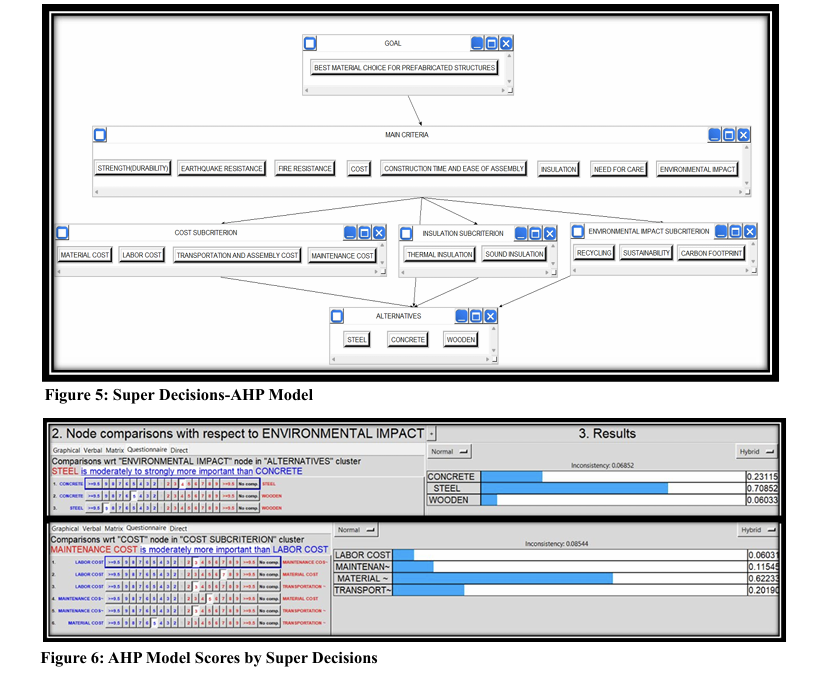

For the solution of the problem, alternatives, criteria, and sub-criteria for some criteria were determined. Then the AHP model was established on the Super Decisions package program. Afterward, the scoring of the criteria was carried out in line with the opinions of the professors who specialized in the main branch of building materials of civil engineering. In the survey conducted by the academicians who are experts in their fields, the geometric mean of the scores was taken for the scoring of the mentioned criteria in cases where different scores were in question.

All pairwise comparisons in the model were scored on the Super Decisions package program.

Conclusion and Recommendations

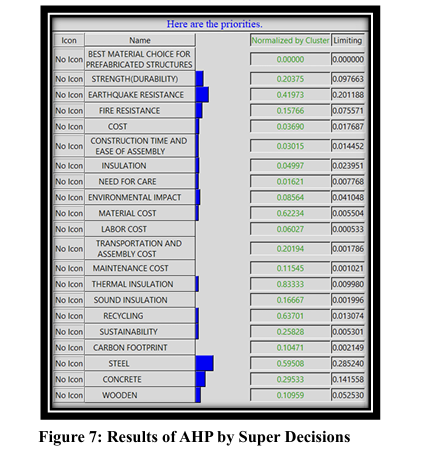

Prefabrication covers construction work using prefabricated elements or components. The prefabricated construction system, which emerged as a result of industrialization in the building sector, provides various advantages throughout the life cycle of structures. In this article, the materials commonly used in prefabricated construction systems were analyzed. In order to select the optimum material, the most important criteria and sub-criteria in the prefabricated building construction process were determined. As material alternatives, the most commonly used materials in the construction industry were evaluated such as steel, concrete and wood. The problem was solved by using AHP method with Super Decisions package program. The model of the program was created and the scores given by the experts in the field were entered into the program. The results of the problem solved in the Super Decisions package program are given below.

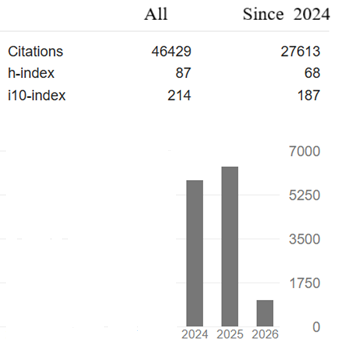

For the most optimum material result of the AHP model, the 1st alternative was determined as steel with a value of 59.508%. The 2nd alternative was obtained as concrete with a value of 29.533% and the last alternative was obtained as wood with a value of 10.959%. As a result of the scoring of the criteria determined for the selection of the optimum material in prefabricated buildings, the most important criterion was earthquake resistance with a value of 41.973%. These criteria are followed by strength (durability) with a value of 20.375%, fire resistance with a value of 15.766%, environmental impact with a value of 8.564%, insulation with a value of 4.997%, cost with a value of 3.690%, construction time and ease of assembly with a value of 3.015%, and need for care with a value of 1.621%.

In the hierarchical order, some main criteria also have sub-criteria. The importance rankings of the main criteria with sub-criteria are environmental impact at 8.564%, insulation at 4.997%, and cost at 3.690%. The importance percentages of the main criteria with sub criteria are as follows: recycling with 63.701%, sustainability with 25.828%, and carbon footprint with 10.471% for the sub-criteria with environmental impact. For the sub-criteria of the main criterion of insulation, the order of importance is thermal insulation at 83.333% and sound insulation at 16.667%. Finally, for the sub-criteria of the cost main criterion, the importance rankings among themselves are material cost at 62.234%, transportation and assembly cost at 20.194%, maintenance cost at 11.545%, and labor cost at 6.027%. Using the AHP method, the importance ranks of alternatives, main criteria, and sub-criteria were determined. The most optimum material to be used in prefabricated building systems was analyzed by the AHP method and the result of the most optimum material to be used in prefabricated buildings was found as steel construction material.

There may also be prefabricated systems consisting of a combination of the three main alternative materials or a combination of several of these materials. Mixed systems can be created by integrating different building materials. For example, steel construction can be used as the carrier system for the exterior facade and concrete prefabricated panels can be used for the interior walls. In short, the materials of the prefabricated elements to be produced according to the project situation may differ from each other. When creating a mixed system, the behavior of the building materials and the expectations of the customer are at the forefront. In this context, it can be suggested to consider mixed structures that will be created by combining the advantageous properties of different materials. In this way, the advantages of each material can be maximized. At the same time, while selecting the most suitable material, it may be recommended to evaluate with different multi-criteria decision-making methods. In this way, the results of different methods can be examined.

Steel and concrete prefabricated building visuals were taken from “Aysteel Light Steel Building Systems” company and wooden prefabricated building visuals were taken from “Narin Building Project Desing- Application” company.

References

1. Turan, G. (2018). Multi-criteria Decision Making. In B. F. Yıldırım ve E. Önder, Multi-criteria Decision-Making Methods (p. 15-19). Ä°stanbul: DORA.

2. Zavadskas, E. K., VilutienÄ?, T., Turskis, Z., & Šaparauskas, J. (2014). Multi-criteria analysis of Projects’ performance in construction. archives of Civil and mechanical engineering, 14, 114-121.

3. Amil, A. Aydın, A. Main Design Principles of Prefabricated Buildings, Atatürk University, Faculty of Agriculture Magazine. 35 (3-4), 235-240, 2004.

4. OdabaÅ?ı, Y. 2000. Wood and Steel Structural Elements, Beta Printing and Publishing Distribution.

5. Roik, M., Tietze, M., & Kahnt, A. (2022). A revival in façades: Textile reinforced concrete panels are light, safe and aesthetically pleasing.

6. Gunawardena, T., & Mendis, P. (2022). Prefabricated building systems—design and construction. Encyclopedia, 2(1), 70-95.

7. Smith, R. E. (2010). Prefab architecture: A guide to modular design and construction. John Wiley & Sons.

8. Å?ahin, A. (2017). Robot Selection Using AHP and TOPSIS Multi-criteria Decision-Making Methods in a Fuzzy Environment, PhD Thesis, Gazi University Institute of Science and Technology, Ankara, 109-131.

9. Zopounidis, C., & Doumpos, M. (2002). Multicriteria classification and sorting methods: A literature review. European Journal of Operational Research, 138(2), 229-246.

10. Khan, A. U., & Ali, Y. (2020). Analytical hierarchy process (AHP) and analytic network process methods and their applications: a twenty year review from 2000-2019: AHP & ANP techniques and their applications: Twenty years review from 2000 to 2019. International Journal of the Analytic Hierarchy Process, 12(3).

11. Saaty, T. L. (2004). Decision making—the analytic hierarchy and network processes (AHP/ANP). Journal of systems science and systems engineering, 13, 1-35.

12. Zahedi, F. (1986). The analytic hierarchy process—a survey of the method and its applications. interfaces, 16(4), 96-108.

13. DaÄ?deviren, M., Akay, D., Kurt, M. (2004). AHP and its Application in Job Evaluation Process, Gazi University, Faculty of Engineering and Architecture Journal 19, p.2, s.132.