Research Article - (2024) Volume 1, Issue 1

An Article Review on Vision-Based Defect Detection Technologies for Reinforced Concrete Bridges

2PhD Candidate, Structural Engineering Department, Ain Shams University, Egypt

3Professor, Computer and Systems Engineering De partment, Ain Shams University, Egypt

4Associate Professor, Structural Engineering Depart ment, Ain Shams University, Egypt

Received Date: Oct 18, 2024 / Accepted Date: Nov 14, 2024 / Published Date: Nov 28, 2024

Copyright: ©©2024 Ahmed Mohammed Abdelalim, et al.. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Citation: Abdelalim, A. M., Shalaby, Y., Ebrahim, G. A., Badawy, M. (2024). An Article Review on Vision-Based Defect Detection Technologies for Reinforced Concrete Bridges. Ann Civ Eng Manag, 1(1), 01-17.

Abstract

Bridges are crucial and the most vulnerable element in the infrastructure systems. A major challenge is to maintain bridge structures at a sufficient level of safety. Scheduled inspections in these structures are important to prevent any failure. The requirement of periodic inspection is urgently needed to maintain the bridges in safe operating condition for the public. Visual inspection is currently the main form for the flaw’s inspection. Nevertheless, it is suffering from time consuming and some limitations related to subjectivity and uncertainty. Due to the complexity of bridge structure, automatic defect detection is an urgent requirement for reinforced concrete bridges. In view of this, the creation and utilization of computer vision method has received considerable attention in several applications of civil engineering. Thus, this paper introduces a comprehensive study in computer vision-based defect detection related to concrete bridges. In this study, a detailed survey is undertaken to identify the research problems and the accomplishments to date in this field. Accordingly, 50 studies between peer-reviewed publications and conference papers Scopus found in are reviewed. Through the analysis, the current review divided the image technology into three groups based on: 1) image processing; 2) machine learning; and 3) quantifying the severity of defects by identifying their parameters. This article highlights the difference and the advantages and disadvantages of applying image processing techniques and machine learning. The paper identifies the types of defects detected by image technology in previous studies and their shortcomings in determining some parameters related to those defects. Finally, this research addresses issues related to the efficiency of detection and the main factors to be considered that may help further research in image-based approaches for defect detection effectively in concrete bridges.

Introduction

Systems supporting civil infrastructure gradually deteriorate over time. They may be divided into four categories: roads, bridges, structures, and water and sewer networks. Steel, reinforced concrete, and pre-stressed concrete with supporting and structural elements are the types of bridges that may be classified. The bridge deck, abutment, foundation, expansion joints, railings, bearings, etc. might all be damaged. The fundamental difficulty in bridge inspection programs is the variety of elements that influence RC bridge degradation and cause various problems [1]. Delamination, scaling, spalling, efflorescence, and cracking are various types of bridge degradation that have been identified. Determining the kind, quantity, breadth, and length of flaws on bridges reveals the early stages of deterioration and avoids these kinds of incidents. Detecting and evaluating the degree of defect is an important process that may affect the structure’s capacity in its current stage or in the future [2]. In order to help decision-makers maximize the safety, serviceability, and usefulness of bridges while staying within their financial constraints, Bridge Management Systems (BMSs) have been created. Any effective BMS would use bridge performance measures to assess the current state of the bridge's health. In order to prioritize repair or replacement projects for the bridges in their inventory, the agencies employ a bridge health or condition index as a performance indicator. However, analyzing the condition of structures to predict their status is not always possible due to a lack of data and inaccurate theoretical models [3].

The majority of existing inspection techniques rely on visual examination. The bridge inspection reporting software has been explored and used by several asset management software developers. Bridge inspection software contains several interactive forms designed for several tasks to make the bridge inspection documentation intuitive. Recently, Building Information Modeling (BIM) proved its ability in inspection and assessment procedures for structures. It provides the user with accurate, less confusing, and well-organized data to help the decision-maker respond and report issues more quickly [4-8]. The previous researches results pointed out that visual inspection alone is unreliable and being disable to indicate correctly repair priorities [1]. Therefore, automatic defect identification is favored for Non-Destructive Technologies (NDTs) and has proven to be useful for quick and accurate surface defect analysis. NDTs, including infrared and thermal, Ground Penetrating Radar (GPR), Ultrasonic Surface Wave (USW), and image-based methods, have recently been applied in the inspection process to carry out a more precise evaluation of surface and subsurface defects [9]. Due to the availability of affordable and simple-to-use visual sensor technology, computer vision approaches for non-destructive inspection (e.g., digital cameras) are growing and developing. Because of the easiness of processing images, several image-processing detection approaches have been developed [10].

As a result, this paper aims to identify the importance of bridge visual inspection in condition assessment of reinforced concrete bridges and how they evolve based on computer vision to indicate its weakness and strength points. The review attempts to assess the capabilities of defect identification based on computer vision. In this regard, the research tries to describe a number of cutting edge computer vision approaches that are used to automate the fault identification process in a variety of patterns. It is explained how these methods were created, used, tested, and assessed in order to identify various flaws in reinforced concrete bridges.Extraction of the characteristics of faults in order to gauge their severity presents a problem in addition to defect identification. The purpose of this work is to address the shortcomings of computer vision-based approaches, which are the most popular ones for assessing the state of bridges. Additionally, it assists researchers in locating and addressing any gaps in the body of existing literature as well as in their hunt for new advancements in computer vision based techniques. The research methodology, the significance of the study, discussions, and limitations, are presented, followed by the conclusion. The significance of this article review is related to its ability to provide a good understanding of the development of computer vision-based methods within the last decade. It identifies the shortcomings in the detection procedure for future research.

Research Methodology

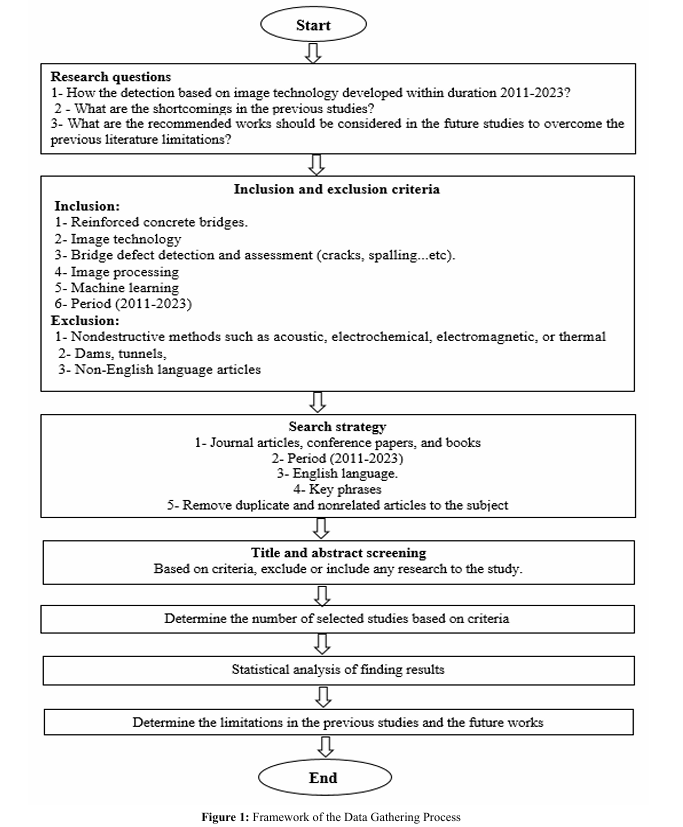

The paper presents a comprehensive synthesis of the state of the art in concrete bridge defect detection and recognition related to computer vision-based methods. The first step is to concentrate on three questions to be answered through the study:

1. How was the detection based on image technology developed within the period 2011–2023?

2. What are the shortcomings of the previous studies?

3. What are the recommended works that should be considered in future studies to overcome the previous literature limitations?

Secondly, the inclusion and exclusion criteria are determined to build up the research based on them. Keywords, such as visual inspection, camera image, concrete bridges, bridge detection, image processing, machine vision, and deep learning are used. Journal articles, conference papers, and books were only taken into consideration in this review. The search period is limited to the period between 2011 and 2023. The predefined exception criteria such as non-English language articles, duplicate, and nonrelated articles to the subject of concern are applied.

The articles that use images collected by digital cameras, small robots, UAVs, or from public datasets such as SDNET2018 or ImageNet are only considered in this review. Accordingly, a sample of 50 articles is selected for this study. The results are characterized by year of publication, country of publication, publication type, defect type, and the measurement of defect parameters based on image technology. Finally, the limitations and future work are discussed at the end of the research. Figure 1 shows the detailed framework of the data-gathering process in this review.

Evaluation of Bridge Defects Based on Visual Inspection Technique

Bridge inspections give engineers the opportunity to detect small and potential defects areas in bridges before they convert into major issues and lead to a catastrophic incident, such as a bridge failure or a complete collapse of the bridge. The main form of assessing the physical and functional conditions of civil infrastructure is the manual visual inspection. The main advantage of visual inspection is that it includes an extensive evaluation of the entire bridge and is not restricted to the detection or assessment of a particular type of damage or a component of the bridge. Its cost amount determined based on the characteristics of the bridge and the level of inspection details and frequency. The main elements of the visual inspection costs are traffic management and labor [1]. This technique of inspection is still mainly relying on human eye observation. It is required expert maintenance engineer to be on the field to decide whether the maintenance condition is required. It needs a lot for preparation on both inspection planning and expertized identification. Actually, the number of specialists in the field is inadequate comparing to the number of bridges to be inspected. Thus, it is suffering from many drawbacks that has a potential threat on personal safety and caused a lot of accidents. For example, the collapse of the I-35W Highway Bridge in Minneapolis (Minnesota, USA) in 2007. The National Transportation Safety Board reported the major issues related to, the insufficient use of technologies for accurately assessing the condition of gusset plates on deck truss bridges; and the shorting of inspection guidance for conditions of gusset plate distortion [9,11]. Bridge inspection data shows 46% of collapsed bridges were structurally deficient before the collapse. It gives an indication for requirements of an efficient maintenance strategy for detecting the drawbacks of the structure [12].

The Canadian infrastructure report card identifies that 26% of the bridges are either ‘‘Fair,’’ ‘‘Poor,’’ or ‘‘Very Poor’’ and one third of their bridges were reported to have structural or functional deficiencies with short remaining service lives. The average age of bridges in 2007 was 24.5 years compared with a mean service life of 43.3 years, which gives an indication of 56% of the estimated service life had already passed. Moreover, the accumulation cost of bridge maintenance, rehabilitation, and replacement is estimated to be Can$10 billion. The continuous increase in the backlog is a remarkable of a significant deterioration in the condition of bridge elements. Therefore, an evaluation of the condition of bridge decks and other components is an essential to keep them in a safe condition and to ensure public safety. It is worth highlighting that the condition ratings are susceptible to mistakes since the visual inspection-based techniques are heavily dependent on the inspectors’ abilities and their experiences [13].

The authorities around the world have a desired to develop solutions to periodically inspect their bridges and to support maintenance activities. The US and the EU have developed numerous Bridge Management Systems (BMSs) to assist engineers in the condition assessment and prioritization of maintenance activities. The system is consisting of five interconnected modules; a database, condition and structural assessment modules, a deterioration prediction module, a lifecycle cost module, and a maintenance optimization module. The database stores inventory and evaluation data. The existing health condition of the bridges is as a performance indicator evaluated by the condition assessment module. The future condition of bridge components is estimated by the deterioration prediction module. The life-cycle cost module is responsible for calculating agency and user costs for different maintenance choices. The optimization module defines the most cost-effective maintenance strategies [14]. Generally, BMS is a visual inspection-based decision-support tool would use bridge performance measures to assess the current state of the bridge's health to prioritize repair or replacement projects for the bridges based on their inventory.

Laterally, the inspectors found that onsite inspections require closing bridge systems or diagnosing them, due to limited human resources. Therefore, several research groups have proposed structural health monitoring (SHM) techniques. This technology is referred to the process of implementing monitoring systems to measure in real-time the structural responses, in order to detect anomalies and/ or damage at early stages. Although the SHM approach is an effective bridge management tool, it still has several challenges for monitoring large-scale civil infrastructures due to various uncertainties and nonuniformly distributed environmental effects. It requires covering large-scale structures, and dense instrumentations, such as fixing numerous sensors, integrating data from distributed sources, and consideration of environmental effects. In addition, checking the sensing systems and structures in person must be done first to confirm whether the collected data actually indicate structural damage, sensory system malfunction, noisy signals, or a combination of these. Thus, it needs further research to be a simple, reliable, and low-cost option to become a standard part of BMS [1,15].

However, current inspection practices depend on visual inspection and basic tools, such as hammer sounding and chain drag to determine subsurface defects such as delamination [16]. These techniques suffer from some limitations such as time consumption, subjectivity, uncertainty, and the inability to detect all subsurface defects [17]. Therefore, numerous authorities tend to use computer vision-based methods in the inspection process to evaluate concrete surface structures. This technology improves the inspection process, and speed, and eliminates the need for traffic disruption or total lane closure. It is not only used for defect detection but also to evaluate their severity [18]. Recently, image acquisition applications have been used by expert assistance and cameras to capture the image of bridge components and then send them to the server of the Department of Highways in order for the expert to verify them in the office. Nevertheless, image acquisition application still needs human observation to check images one by one [11]. In order to automate the process of defect and damage identification as well as evaluation, this section seeks to describe a number of cutting-edge computer vision approaches to make the system become intelligent and automatic.

Defect Detection Image-Based Technology

Methods based on visual inspection assist transportation organizations in identifying shortcomings and making decisions that are more accurate and objective [9,10]. However, without eliminating various types of noise associated with diverse sources, such as concrete blebs, stains, uneven contrast, and shading, an image-based technique cannot be useful [19,20]. Hence, there are three approaches to executing picture-based inspections: raw image inspection, image enhancement, and autonomous image processing. The term "raw image inspection" refers to the inspector's unprocessed evaluation of the images that are taken during the inspection process. Depending on a variety of criteria, the total number of images captured is typically hundreds or thousands. This manual identification takes time, and it frequently results in errors because people make mistakes. Performing various image processing methods to enhance image inspection makes it simpler to spot problems in inspection images. Morphological operations, digital image correlation, image binarization, percolation model, wavelet transformations, fractal analysis, and edge detection methods are used to achieve this task, which significantly improves the appearance of fractures inside pictures. Last but not least, autonomous image processing is the application of an algorithm that finds flaws in images. Using machine learning algorithms or other artificial intelligence systems, this process can be precisely achieved [21]. To understand the characteristics of flaws, the autonomous system for defect identification needs a collection of training images. Additionally, a lot of studies demonstrate how to integrate image processing methods with artificial neural networks [22].

Defect Detection Using Image Processing Techniques

On image pre-processing and image segmentation for bridge f laws, several researchers established their vision. A method based on image processing is put forth by Tong et al., for the identification of cracks in concrete bridge bottoms [23]. The numerous lights under bridges presented a problem. The model is developed to assess whether or not binary pictures could identify fractures based on factors including region circularity, aspect ratio, perimeter, and area. In order to adjust the average grey-level values of a single image, the color images are first transformed into red-green-blue (RGB) format. The noise can be eliminated by using a Gaussian filter. To ensure the connection between crack segments, morphological treatments including dilation and thinning are carried out. Then, the segmentation threshold is used to turn grayscale images into binary images to represent fractures. A comparison with three traditional techniques (Cany, Soble, and Fujita's) is conducted, and the accuracy of crack detection is improved by 1% to 6% and achieved by 93%.

The crack tree is created by Zou et al., as a completely automated technique for locating and identifying fracture curves in pavement images. The process for the suggested solution includes a crack detection algorithm, a crack seed, and a tensor voting methodology to produce a crack probability map in addition to a shadow removal algorithm. Images are divided into regular and complicated images by Chanda et al [14,24]. Before the characteristics of cracks or non-cracks are retrieved from the complex images, some pre-processing processes are required. In order to isolate image intensity from color information, the complex image is first converted from RGB format to the Hue Saturation Value (HSV) color space. The complicated image is then converted into a comparable greyscale image. Wavelet is more accurate than the Gabor filter, according to characteristics that are extracted from a comparison of the two. For segmentation, Lattanzi and Miller suggest an automated clustering technique based on Canny and K-Means to achieve high speed and accuracy of fracture identification in a variety of environmental situations [25]. As is frequently the case with real-world bridges, the significance depends on the capacity to train images from various angles and is linked to variations in lighting and shading conditions at various points on the bridge. Adhikari et al., proposed a comprehensive model based on image processing techniques for routine inspection of reinforced concrete bridges [26]. The proposed technique was composed of models for crack quantification, change detection, neural networks, and 3D visualization models. The stitching algorithm was adopted to extract the invariant features from photos and compare them with new images. Segmentation and edge detection algorithms were applied for crack detection.

Using a variety of image processing approaches for bridge fracture detection and classification, Chen et al. proposed an ascending robot model. The collected images are motion-blurred; thus, the motion blur is removed using a Wiener filtering technique [27]. The Wavelet transform is used to reduce the textural impacts in the fracture area. In order to categorize cracks and determine their severity, a Support Vector Machine (SVM) is used. A novel straightforward technique based on Otsu method for fracture identification in concrete buildings was introduced by Talab et al., in 2016 [28]. This approach involved the use of many filters, including Sobel, Area, and Otsu methods for fracture detection. The suggested method performed better than existing binarization techniques. Noh et al. suggested utilizing fuzzy C-means clustering in segmentation to find 0.3mm fractures in images [29]. In this approach, a series of processes including segmentation, morphology, and filtering is used to improve the visibility of fracture features and eliminate background noise. First, fuzzy C-means is used for image segmentation. Second, morphological dilation is used to reveal fracture characteristics, after which manually calibrated masks for filtering are made. Finally, related noise locations are located and removed using a Grassfire search. In comparison to existing edge detection-based approaches, it is emphasized that the developed method achieves greater recall and precision.

Safae et al., developed a tile based on an image-processing algorithm to detect pavement cracks [30]. It was suggested to use a technique of localized thresholding on each tile to identify cracked ones (tiles with cracks) based on the spatial distribution of crack pixels. The method showed some problems related to detecting low-level cracks in complex patterns. De León et al., presented a methodology for crack segmentation based on the theory of minimal path selection combined with a region-based approach obtained through the segmentation of texture features extracted using Gabor filters [31]. An equalization of brightness and shadows is a pre-processing step to improve the detection of local minima. To improve the coverage of the cracks, these local minimal are constrained by a minimum distance between adjacent points. Subsequently, two areas are identified using a region-based segmentation technique, which establishes the threshold values for rejection. Lastly, a geometrical thresholding step is presented, which enables the exclusion of small, isolated cracks and rounded areas. Although a number of automated crack detection models have been established, they have some drawbacks. While the algorithms of the machine and deep learning have shown promise in the previous ten years, they have some shortcomings: A "black box" design of neural networks and deep learning leaves the users blind and prevents them from changing any parameters; a significant quantity of labeled data is needed; and lastly, they typically take a long time [31]. Dow et al., used image processing techniques to establish a novel method for binary noise removal and segmentation of noisy concrete crack images [32]. The method is based on thinning noisy crack image into skeleton then uses morphological reconstruction to eliminate all of the noisy picture's features that do not intersect with the skeleton. The obtained recall, precision, intersection over union, and F1 score results were 77%, 91%, 72%, and 84%, respectively.

Defect Detection Using Machine Learning Techniques

Machine learning (ML) algorithms have achieved big successes to enable computer-aided defect detection through automatic classification. The pre-processing of an image is sometimes an initial step to extract the features that would be used to train the machine learning classifier. Also, it can be used to enhance or eliminate properties of the image that could improve the performance of the machine learning algorithm. The following sections will clarify how various types of machine learning are applied for flaw detection and classification.

*Artificial Neural Network (ANN)

In order to help inspectors quickly evaluate and see cracks, Moon and Kim create an automated crack detection method that utilizes a set of image processing techniques [22]. Directly from the source images, the cracked and non-aliased images are classified using an Artificial Neural Network (ANN). ANN is used in conjunction with image processing processes to speed up computation for training images that require a lot of data. The first step in image processing is to turn a color digital image into a grayscale one. Then, the uneven illumination is eliminated from the gray-level image by utilizing a median filter and an enhanced subtraction technique. To close the minor gap in the crack line and to correct the distortion in the crack form, a Gaussian Low-pass filter is used. Without consulting professionals, it is possible to adjust parameters such as the median filter size, threshold values, Gaussian filter size, and the standard deviation of the Gaussian curve using the Taguchi approach based on a level with the maximum signal-to-noise ratio. As a result, the fracture may effectively be separated from the backdrop. In order to label images into cracked and non-cracked concrete photographs, an artificial neural network is designed. The designed model is able to identify 90% of the cracked images and 92% of non-cracked images.

*Convolutional Neural Network (CNN)

Convolutional Neural Networks-based two-stage crack detection methodology is reported by Li et al. in 2018 [33]. To determine the likelihood that a pixel is a part of a cracked region, a tiny patch centered on each pixel is initially given into the predictor. A larger area taken from the first confidence map is created by the f irst predictor and put into the second predictor to create a second confidence map constitutes the second stage. The final confidence map, which is utilized to improve the cracked area, is created by merging the two confidence maps. In terms of accuracy, precision, and sensitivity. The newly developed approach outperformed the canny edge detector method and the spatially tuned robust multi feature (STRUM) method.

*Deep Learning Technique

Later, the researchers considered applying deep learning a kind of machine learning that is based on deep neural networks with several hidden layers to extract and learn high-quality characteristics from images [34]. Convolutional neural networks (CNNs), recurrent neural networks (RNNs), long short-term memory (LSTM), encoder-decoders, and generative adversarial networks (GANs) are the most popular deep learning architectures employed by the computer vision field. Convolutional neural networks (CNNs) are used by Cha et al. to identify concrete fractures without connecting Image Processing Techniques (IPTs) for feature extraction [15]. The created model considers issues with crack identification such as illumination, shadow casting, and blur. The model performance is compared with that of the classic Canny and Sobel edge detection techniques in a variety of settings, including uniform, normal illumination, narrow crack cases, and shadow cases. In terms of training and testing accuracy, it fares better than the other two approaches with 98.22% and 97.95%, respectively.

Modarres et al., used CNN to detect cracks in concrete surface bridges [35]. The CNN model's feasibility is tested using two images: a noisy set of textured concrete surfaces with visible cracks representing in-service structures in a visual inspection, and a clean set of well-controlled surfaces with varied lighting conditions representing concrete in new bridges. According to the results, the proposed CNN performs better at crack detection for both images sets than other machine learning models, such as random forest, and SVM with non-linear kernel. Zhu & Song enhanced a weakly supervised network for crack detection in asphalt concrete bridge decks [36]. The methodology includes an autoencoder for data differentiation, and features for unlabeled data were highlighted to generate a starting point for convergence. Then, K-means clustering was applied for classification. Lastly, semantic segmentation under weak supervision was applied on the crack image of the bridge deck. Li et al. adopted the fully convolutional network and a Naive Bayes data fusion (NB-FCN) model for crack detection in bridge substructure [37]. The model considered the different illumination and distance for images taken.

Meng et al., used You Only Look Once version 3 (YOLOv3) to detect cracks at pixel level [38]. The model is able to locate several defects, such as cracks, spalls, exposed tendons, and free lime. Chen. improved a convolutional neural network to determine whether foundation piles on concrete bridges are unstable [39]. The improvement was based on the replacement of the SoftMax layer with a support vector machine (SVM). The model achieved an average recognition rate of 96.26%. The limitation of this method was related to its ability to be applied for different types of pile foundations. Yu introduced a proposed model for crack detection based on a Generative Adversarial Network (GAN) [40]. The accuracy result was 24.78%, and the recall rate was 19.64%, which was lower than other deep learning types.

*Transfer Learning Technique

Transfer learning is a method for supervised learning that employs a pre-trained network as a starting point for additional training to alleviate the issue of data collecting and extensive training time [41]. In order to find fractures in an old concrete bridge, Kim et al. present a technique utilizing a commercial UAV with a high resolution vision sensor [42]. In this model, transfer learning and a region-based convolutional neural network model are used to scan the important area of the picture swiftly. For crack quantification, various image processing techniques are also conducted. Additionally, the Cifar-10 dataset is used for pre-training the deep neural network model. In quantifying cracks, the model obtained a relative inaccuracy between 1% and 2%.

A pre-trained deep convolutional neural network dubbed "Halcon" is used by Kruachottikul et al., to identify flaws in bridge substructure surfaces [11]. They are utilized for pre-processing, augmentation, splitting, and overlaying images. After that, CNNs are used to classify images. The generated model has a total accuracy of 89%. Xu et al., introduce a model based on the convolutional neural network for the purpose of detecting cracks in bridges [43]. The Atrous convolution is used by the Atrous Spatial Pyramid Pooling module is applied to avoid the reduction of image resolution and to extract the multi-scale crack feature information. Additionally, depth-wise separable convolution is used after the convolutional layer to reduce the computational complexity and the model parameters. The proposed model gained 96.37% of accuracy without pre-training and outperforms several classic classification models.

In order to identify fractures in concrete, Dorafshan et al., compared standard edge detection and DCNN methods [21]. In the spatial domain (Roberts, Prewitt, Sobel, and LoG) and frequency domain (Butterworth and Gaussian), a total of six edge detection techniques are used. Three different modes of the Alex Net DCNN architecture are used: fully trained, classifier, and fine-tuned. When compared to other approaches, the LoG method has the best accuracy (79%) for locating cracks larger than 0.1mm. While the transfer learning mode of the DCNN has the best accuracy (86%) and could identify fractures larger than 0.04mm. Based on two types of Deep Learning Convolutional Neural networks, Dorafshan et al. explored the feasibility of employing small Unmanned Aerial Systems (sUAS) to monitor concrete decks and structures [44]. On the training dataset, a convolutional neural network powered by AlexNet is fully trained in the first mode. In the second mode, the same architecture that has been previously trained using the ImageNet dataset is used for transfer learning. The testing dataset is obtained using tiny unmanned aerial systems, whereas the training dataset of bridge decks is recorded using a Nikon COOLPIX L830 camera. Three datasets serve as the foundation for the neural network assessment. The fully trained mode training and validation processes took longer to complete than those for the transfer learning mode. It is observed that the transfer learning outperformed the fully trained network in terms of accuracy. Zhao et al. presented an inspection technique for bridge maintenance [45]. The first part was built to determine the type of bridges, e.g., suspension, and cable-stayed bridges, by using AlexNet. Second, a Faster-RCNN is trained to classify the bridge components (e.g., tower, deck). Finally, GoogLeNet was used for concrete crack detection. Nevertheless, this proposed method suffers from a lack of discussions of the connections between the three previous components.

In the example of a small dataset, SÅ?oÅ?ski compares four convolutional neural network designs and training approaches for identifying fractures in concrete pavements [46]. A tiny convolutional network that is built from scratch with and without data augmentation, a big pre-trained VGG16 with data augmentation, a large, pre-trained VGG16 combined with data augmentation, and fine-tuning are the four comparisons that are used. The pre-trained VGG16 coupled data augmentation and fine tuning is reported to have the greatest performance classification, reaching training and validation accuracy of 95% and 93%, respectively. A crack detection technique based on a deep fully convolutional network was introduced by Dung and Anh in 2019 [12]. On a public concrete crack dataset used as the encoder of the fully convolutional network, three distinct pre-trained models, including VGG16, Inception V3, and ResNet, are assessed for picture classification. Except for the fully connected and Softmax layers, the encoder includes all the VGG16's convolutional and pooling layers. For crack image categorization, VGG16 fares better than the other two relevant networks. On a subset of crack pictures from the same dataset, the encoder-decoder fully convolutional neural network architecture is trained end-to-end for the segmentation task. On the training, validation, and test sets, the proposed segmentation approach achieves a maximum F1 score and average accuracy score of almost 90%.

Hüthwohl et al., introduced a three-staged hierarchical structure multi-classifier for bridge defects. The model includes fine-tuning three independent, pre-trained deep neural networks [47]. However, the model couldn’t classify some types of defects because of the unavailability of a larger labeled dataset. Zhu & Song enhanced the structure of VGG-16 for the purpose of classifying defects on concrete bridges [48]. The number of fully connected layers was reduced, and seven defect tags on the SoftMax classification layer took the place of the SoftMax classifier. The seven groups of defects—normal, cracks, fracturing, plate fracturing, corner rupturing, edge/corner exfoliation, skeleton exposure, and repairs—were effectively differentiated by the model. Deng et al., used a transfer learning model and CNN for bridge defect detection [49]. The model classified damage into delamination, rebar exposure, and non-damage with an accuracy of 97.8%. In contrast to conventional methods, Zhu et al., employ a mix of CNNs and transfer learning for the identification of bridge flaws [41]. They use the ImageNet-trained Inception-V3 program to automatically extract features from images. A transfer learning model is trained on images with arbitrary pixel resolutions and sizes. The performance of the suggested technique is then investigated using SVM and artificial features such as Histogram of Oriented Gradient (HOG) and Gray-level co-occurrence matrix (GLCM). The selected model encouraged bridge fault identification at an intelligent management level.

A self-adaptive hybrid SVD-ENN-IWO approach for the automated detection and identification of surface defects is developed by Abdelkader et al., in 2021 [13,18]. The output of this model reveals whether or not the image has flaws. The result for identifying bridge defects is if the image has scaling, spalling, or cracking. Using Singular Value Decomposition (SVD), which eliminates superfluous characteristics and reduces complexity data, it is possible to extract the image key features. The singular values of the retrieved feature vector-based images are then computed using this method. The Elman Neural Network (ENN) then receives this feature vector set as input. The primary goal of Invasive Weed Optimization (IWO) is to improve the way that the ENNs are trained. The developed model outperforms other models such as CONVNET, AlexNet, VGG16, VGG19, and CaffeNet.

For crack detection and recognition in three different forms of infrastructure, including bridges, roads, and buildings, Abdelkader selects the VGG19-KNN-DE model. In order to eliminate noise from images for feature extraction, the Frost filter is used [13,18]. After that, VGG19, a pre-trained architecture, is employed for the automatic extraction of both local and global contextual data at many scales. For the automatic detection and identification of surface cracks, the resulting feature vector of pictures is utilized as input into the integrated model K-Nearest Neighbors and Differential Evolution algorithm (DE). In identifying and detecting the fractures, the generated models perform better than a group of commonly used machine learning and deep learning models. Cardellicchio et al., introduce an approach through machine learning for defect detection of reinforced concrete bridge elements [50]. The study divided the defects into seven groups: (1) corroded/oxidized steel reinforcement, (2) cracks, (3) deteriorated concrete, (4) honeycombs, (5) moisture spots, (6) pavement degradation, and (7) shrinkage cracks. The neural network was trained to classify single defects vs. all defects. InceptionV3 and ResNet50V2 as classic models, and DenseNet121, MobileNetV3, and NASNetMobile were used for network training. However, the approach required to increase and improve the data quality and enhance the hyperparameter optimization.

Kruachottikul et al., proposed an approach consisting of three components: image acquisition, defect detection, defect classification, and finally severity prediction for bridge substructure [51]. The study used modified ResNet-50 CNN for defect detection. Image processing was applied for defect information such as defect size and number of defects. Also, a modified ResNet-50 CNN model was used for defect classification into cracking, erosion, honeycomb, scaling, and spalling. Finally, Artificial Neural Networks (ANN) are used to predict whether a defect is severe or not. The limitation was concentrated on a shortage of data. Ebenezer et al., proposed three ensemble models for crack detection [52]. The ensemble model used customized CNN and two transfer learning models: Xception and AlexNet. The accuracy of the ensemble transfer learning model achieved was 87.1%.

Zoubir et al., improved VGG-16 with transfer learning to detect three common concrete defects: cracks, efflorescence, and spalling [53]. A VGG16 network was trained using three different transfer learning algorithms with different numbers of layers on the proposed dataset. The performance of the model was evaluated in each learning configuration and achieved an accuracy of 97.13 %. Li et al. used three different UAVs for determining the best distance for imaging for crack detection by the Faster Region Convolutional Neural Network (Fatesr R-CNN) algorithm based on VGG16 transfer learning [54]. The method found that the angle shooting less than 30 degrees was the maximum distance for crack recognition

Defect Assessment

To determine the severity of faults, it is crucial to measure their features, such as depth, breadth, and length. As a result, this section demonstrates the application of image-based algorithms to analyze surface flaws in order to determine the state of bridges.

* Defect Assessment Using Image Processing Techniques

An automated approach for extracting crack parameters such as length, direction, maximum width, and average width was presented by Zhu et al., in 2011 [55]. To locate crack spots on each concrete structural element surface, a percolation-based crack detection approach is used. The crack skeletons are retrieved using this approach, and the crack parameters are extracted by measuring each crack skeleton point to the crack border using a binary image thinning algorithm and a Euclidean distance transform. When these measurements of the crack characteristics are contrasted with hand measurements, the average measurement error for orientation is 3.29°, the relative crack length is 2.21%, and the relative maximum crack width is 0.35%. Ge et al. use an encircle approach and image processing to determine fracture width [56]. The approach began with image processing that includes adaptive thresholding, morphological closure, and erosion procedures. The skeleton points then each acted as a circle center. The circle's radii progressively grew larger. Any point in the circle that stepped outside the crack caused the iterations to stop. As a result, the fracture is encircled by the final circle of the repetition. The diameter of the circle is finally considered as the fracture width in a certain skeletal location. After obtaining all the encircles with all the skeleton points, the maximum and average width of the crack is determined. Adhikari et al. proposed a novel technique to extract the width, length, depth, and densities of the crack [26]. After detecting cracks based on image processing, skeletonization and Euclidean distance algorithms were used to retrieve crack properties such as length and width. A neural network was trained to predict the depth of a crack based on its width. Also, the proposed model offers a novel technique for detecting changes in fracture patterns over time by using frequency domain analysis Fast Fourier Transform (FFT) of digital photographs. Additionally, the digital photos and image textures were projected to create a 3D visualization in order to show cracks in different faces to calculate its densities.

An automated approach is developed by Jain and Sharma to determine the severity of cracks [19]. The pre-processing of the images includes contrast boosting and histogram equalization. The K-means clustering technique is then used to segment the data. The images are segmented using this approach using various K-means clustering parameters, and it is discovered that a random initialization with Euclidean distance works best. Finally, a crack detection technique using fuzzy inference is utilized to provide a risk score that displays the proportion of dangerous cracks. Spalling became a crucial sign of significant structural element damage. As a result, there has not been much progress in the previous 10 years in the detection and evaluation of spalling on concrete surfaces. A technique to atomically identify spalled spots on the surface of reinforced concrete columns and extract their depth and length is put forth by German et al [57]. To achieve the identification and evaluation of concrete columns, a mixture of image segmentation, template-matching, and morphological techniques are used. The distance between the severely exposed transverse reinforcing bars and the relative length of the amount of spalling along the column vertical direction are used to determine the length of the spalled region along the column. To create a damage map, a local entropy-based thresholding approach is first used. Additionally, by using morphological opening and closing processes, the sounds are reduced. Second, to identify areas of exposed longitudinal reinforcement throughout the damage map, a global adaptive thresholding technique in the CMYK color space is combined with a template matching algorithm. For a set of 70 test images, the findings showed a precision of 81.1% and a recall of 80.2%. They advise further research to be done in order to classify the f indings of spalling properties in more depth. Ong et al., produce a hybrid method combining the shortest method and the orthogonal projection method to measure pavement crack width with irregular boundaries or high curvature [58]. In comparison to the shortest technique and the orthogonal projection method, the hybrid method yields the highest correlation coefficient (0.956) and the least average absolute deviation (1.769).

*Defect Assessment Applying Machine Learning Techniques

A platform for the automatic identification and severity evaluation of spalling in reinforced concrete bridges is introduced by Abdelkader et al. in 2020 [59]. The first module dealt with the preparation of images. The second module is created to automatically identify spalling. With the use of a single-objective particle swarm optimization (PSO) model that tries to increase the image Tsallis entropy, spalling images are segmented using bi level thresholding. This module produces a single threshold T that divides the image pixels into the spalling (foreground) and surface classes (background). The third module is the feature extraction process, which separates the collected images into high pass and low pass filters using Daubechies discrete wavelet transform. The automatic assessment of spalling severities is the final module. With reference to the artificial neural network, the suggested produced spalling evaluation model (ANN-PSO) decreases the prediction errors by percentages ranging from 71.43% to 76.65%. Additionally, in contrast to the created prediction model, the Otsu algorithm is unable to discern spalling pixels in the image. Li et al. used the fully convolutional network and a Naive Bayes data fusion (NB-FCN) for crack detection, followed by a skeletonization process to extract crack properties: width and length, with a mean error less than 0.03 mm for width and 92.8% for length accuracy [37]. Yu et al., used YOLOv5 for the crack detection process [60]. The model adopted to increase the connection accuracy suggested a connected component search strategy based on the crack trend of the area. The model was able to detect cracks wider than 0.15 mm, and the crack width error was less than 0.05 mm.

Bae & An established a computer vision-based crack quantification algorithm incorporated with the deep semantic segmentation network [61]. The crack width is calculated as the range value depending on the statistical confidence interval with a normal distribution of the maximum width. Two cases of crack area were examined to find the maximum width based on the average widths measured at each spotted point along the crack area for each image. The average difference for each case is, respectively, -41.43% and -11.14%. The model fixed the type of structuring element used in morphological operations, which cannot be generalized because of the different patterns of cracks in several images. Kao et al. used YOLOv4 deep learning, which is the integration of the development architecture YOLOv3 for the crack detection process [62]. The images were taken by UAV from distance 1 m. Canny and morphological edge detectors were applied to extract the crack edges. Then, planar marker and measurement feature points were used to measure the crack width in images with an accuracy 92%. Tran et al., applied You Only Look Once version 7 (YOLOv7), a deep learning network, which outperformed both Faster RCNN and RetinaNet with both ResNet50 and ResNet101 in speed and accuracy [63]. Then, the proposed method is used to measure the crack length and width to achieve an average accuracy of 92.38% and 91%, respectively.

Discussion

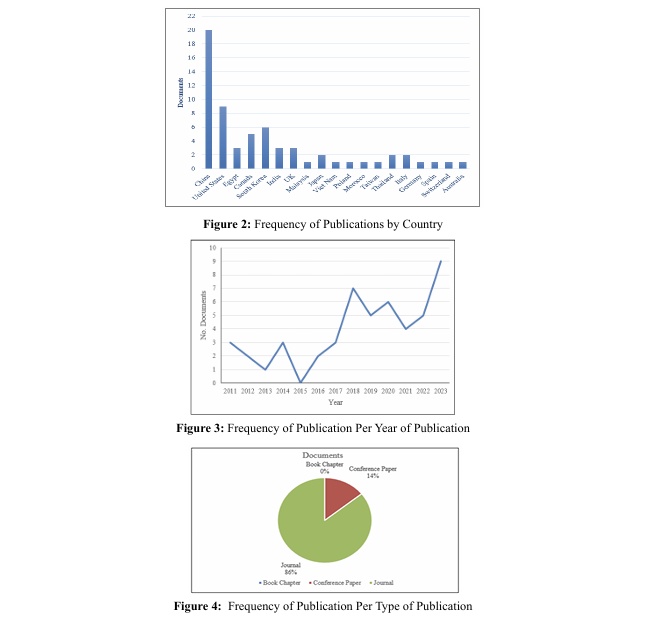

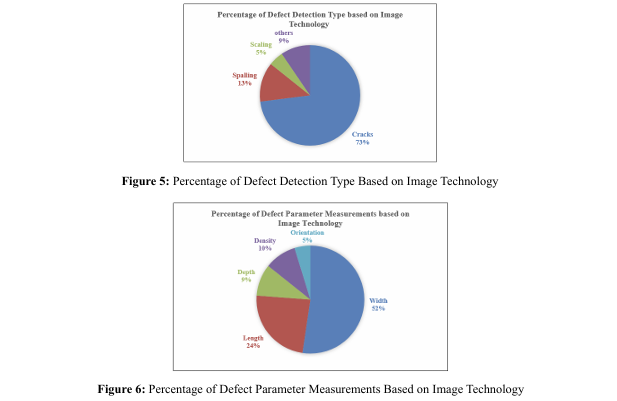

The review highlights the significance and range of computer vision-based applications and models used to evaluate the state of reinforced concrete bridges. The research process used a seven step framework for data collection and results, as shown in Figure 1. The study begins with establishing questions, followed by the definition of conceptual criteria. The research concentrated on keywords such as visual inspection, camera image, concrete bridges, bridge detection, image processing, machine vision, and deep learning. Nondestructive methods that are applied in defect detection or other types of structures, except reinforced concrete bridges such as dams and tunnels, or others, are excluded from this study. In addition, the literature is limited to journal articles, conference papers, and books in English published in Scopus within the period 2011–2023. A total of 300 articles were first identified, and based on the previous criteria, the title and abstract were screened to remove any duplicates and nonrelated articles to the current subject. After this process, 50 documents are discovered using the research approach in the prior time frame. Based on Scopus data, results are separated by publication year, publishing nation, publication kind, defect detection type based on image technology, and defect parameter measurements based on image technology. Eighty five percent of all publications are press pieces, while fifteen percent are conference papers. The literary contributions of several nations are seen in Figure 2. The f indings indicate that China is the top nation for image screening techniques for bridge detection. The number of publications each year shown in Figure 3 illustrates the interest in defect detection using the image-based approach in 2018. Figure 4 shows that only 15% researches related to defect detection based on image technology were discussed in conferences.

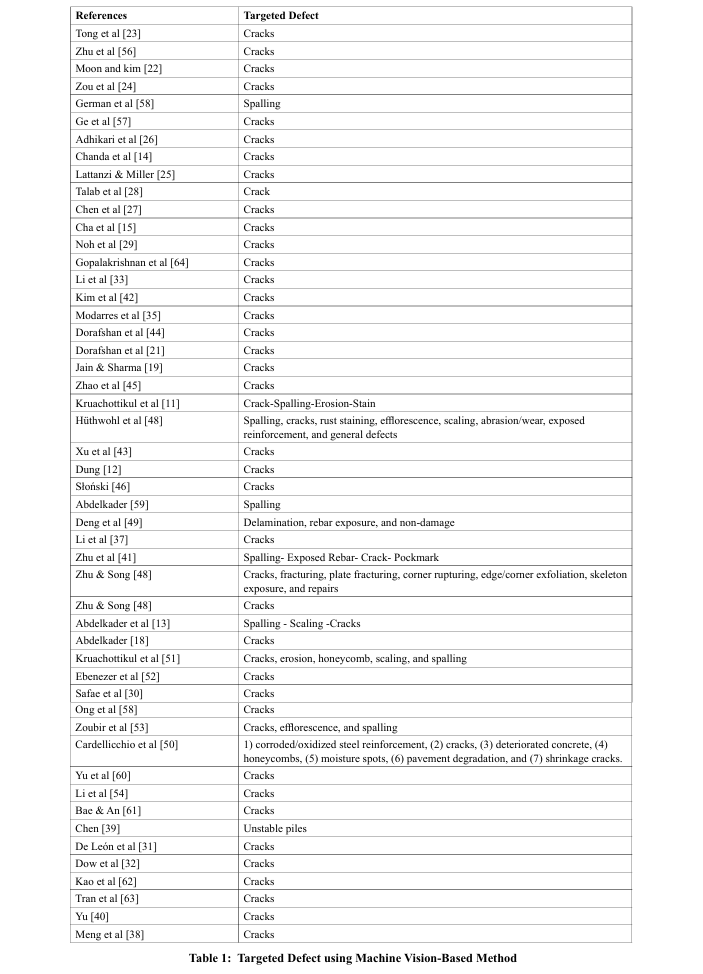

The earlier research may be categorized into three groups: (1) those that identify imperfections or damage; (2) those that pinpoint the imperfections or damaged pixels in the picture to produce a "damage map;" and (3) those that concentrate on assessing the seriousness of the specific imperfections. As can be seen from Table 1, the majority of research focuses on crack identification (73%), while a small number examined additional kinds such as scaling and spalling, as shown in Figure 5. Most of the research focuses on creating novel crack detection techniques, while some compare the effectiveness of already available techniques. Regarding crack identification, it is primarily the work of earlier research that led to the development of a machine vision-based technique for automatically identifying cracked and untracked areas of concrete surfaces. A "crack map" is the result of this machine vision-based technology, which also includes the automated determination of the position of crack sites within the image.

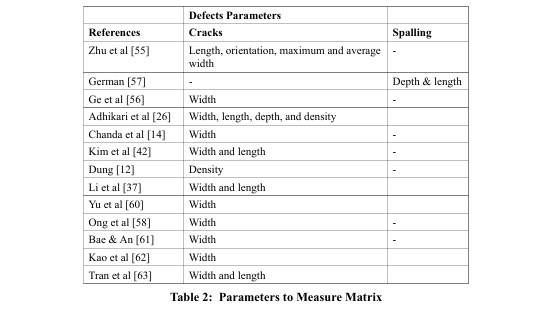

Following filtering, the study findings from Scopus within the years of (2011–2023) discover certain sorts of flaws (cracks, spalling, scaling, erosion, and pockmarks) for identification. Without considering additional nondestructive methods such as acoustic, electrochemical, electromagnetic, or thermal, the review focuses on image-based methods. Due to its effectiveness in overcoming challenges such as accessibility issues, traffic closures, and safety risks to inspectors and the public, bridge inspection based on an Unmanned Aerial System (UAS) has drawn a lot of attention. Image processing and machine learning techniques have been combined for infrastructure inspection, displacement and structural stiffness measurements, and other tasks [21,42]. Additionally, the usage of a deep convolutional neural network in the UAS drew academics to investigate its advantages and efficacy as well as how important it is to employ better cameras on small unmanned aerial systems [44]. Many algorithms are used not only to identify flaws but also to comprehend their properties such as position, breadth, length, and orientation. To properly and fully reflect the defect information, and automatic evaluation, it is required to identify of the pertinent defect parameters. The measure criteria for cracks are length, breadth, density, and direction, as shown in Table (2). In contrast, depth and length are used to determine the degree of spalling. Figure 6 gives an indication that 52% of studies used computer vision technology to measure crack width, while only 24% for crack length.

The majority of earlier studies focus only on the length and breadth of the fractures. It could require specialized non-destructive tools. Furthermore, the case studies are applied to bridge deck surfaces or to columns that are only flat or curved surfaces

Without complicated geometry, such as joints, seals, or bearings, or that have several sub-components and typically have a wide range of material compositions. According to the investigations, image processing techniques (IPTs) are insufficient to distinguish between samples with identical properties, such as cracks versus illumination spots, shadows, and edges. As a result, the feature extractor's capabilities are limited by using just conventional IPTs, and manually extracting features from images is time-consuming. In order to overcome IPTs' limitations in extracting and learning high-quality features, the researchers consider using deep learning techniques.

The biggest barrier to the effective deployment of DCNNs is the unavailability of huge datasets required to train large DCNNs from scratch [46]. Therefore, a pre-trained network is generally used on a large-scale picture classification assignment to address this issue. This strategy demonstrates the efficacy of deep learning on modest datasets for a variety of computer vision issues. AlexNet, VGG16, InceptionV3, and Resnet50 are popular deep convolutional neural networks that have been built. These networks are often trained on huge image datasets, such as ImageNet dataset [12]. AlexNet is utilized by Dorafshan et al. to study its viability in the inspection of concrete decks, and they suggest combining it with other designs such as ResNet to enhance network performance [44]. After that, VGG16 outperforms InceptionV3 and ResNet for crack picture classification, according to Dung & Anh [12]. In order to extract image features, Abdelkader opts to utilize VGG19 rather than VGG16 since training VGG19 requires more computational work than training VGG16, which has 16 trainable layers [13,18]. As a result, VGG19 performs better in crack fault detection and identification than both Alexnet and VGG16 [13,18]. Transfer learning and deep the convolutional neural networks influenced by VGGnet architectures have demonstrated their efficacy in handling challenging image classification tasks and sizable annotated datasets in this regard. Their great ability to extract and acquire deep learning features to distinguish between picture classes-even in computer vision issues when there are classes that are expressly distinct from the original dataset is used to train the pre-trained model [64,65]. It is noteworthy that the crack detection method based on Convolutional Neural Networks outperforms the other edge detectors [15,33]. Additionally, DCNN outperforms edge detection techniques including Roberts, Prewitt, Sobel, Laplacian of Gaussian, Butterworth, and Gaussian in terms of spotting fractures bigger than 0.04 mm [21]. However, the DCNN needs an enormous amount of training data, which consumes a huge computational cost.

Gaps in Previous Research

Based on the literature review conducted, there are some short comings in the computer vision-based methods for detection and assessment. Scaling and spalling are two further sorts of flaws that are not thoroughly inspected. To gauge the severity of a bridging fault, phrases such as "defect" and "no defect" or "crack" and "no crack" are insufficient. Models seldom demonstrate their capacity for assessing flaws in breadth, depth, and length. A few research efforts have concentrated on enhancing the automatic method identification based on computer vision-based approaches for scaling and spalling flaws, in spite of their significance in the assessment of concrete surface problems. The majority of models do not consider environmental factors that might impact the stability and safety of unmanned aerial vehicles (UAVs) as well as the quality of the images that are acquired, such as fog, different lighting, and wind speed [22,66]. Also, the flight altitude and signal delay of the GPS are two factors that influence the use of UAVs to be considered in the image detection method. The distance for capturing images by UAV needs to be considered in the model accuracy. Additionally, due to how the surrounding environment, such as shadows and sunlight intensity, influenced image processing algorithms for defect quantification, certain systems encounter considerable difficulties in quantifying particular faults [42]. As a result, it is necessary to assess the suggested method in a number of application domains. Additionally, the algorithm accuracy needs to be increased. To find the ideal parameters needed for image processing, a variety of optimization techniques can be used. Also, the other parameters of cracks to be extracted, such as orientation and depth, need more studies. Finally, the previous modules cannot be generalized to detect all types of defects for all types of surfaces (walls, asphalts, decks…etc.). Therefore, multi-technology systems must be applied in inspection process to overcome these challenges.

Conclusions

Visual inspection is a major component in bridge condition assessment procedures. The quality and reliability of visual inspection results not only rely on the qualifications and experience of those leading bridge inspections but also on the motivation and equipment of those conducting such inspections. The article shows several models based on computer vision to contribute in maximizing the safety and serviceability of bridges. In remote and up-close images of bridges, various faults, and damage patterns may be found and measured using a variety of approaches. Based on the image-based methodologies, three primary groupings are explored in the papers. While the second group depends on machine learning for automatic detection, the first group mainly depends on image processing techniques. The last group is interested in quantifying the severity of faults by identifying their dimensions, including their length, breadth, area, and perimeter. The study gathered the key problems that will be important for future studies on image-based approaches. To expand the storage capacity of the bridge database, it is hoped that future research will raise recognition speed and accuracy to recognize real-time identification. To create a trained machine-learning classifier that successfully categorizes inspection images, a broad variety of variables in images, including changes in lighting, texture, debris, staining, and contrast should be considered. Finally, future studies should focus on applying image technology not only on cracks, but also on other defects (spalls, scale, delamination…etc.) and concentrating on extracting the defect features such as depth, orientation, and densities [67].

References

1. Omar, T., & Nehdi, M. L. (2018). Condition assessment of reinforced concrete bridges: Current practice and research challenges. Infrastructures, 3(3), 36.

2. Abdelalim, A. M. (2012, May). Quantitive assessment of deteriorated RC structures due to reinforcing steel corrosion. In The International Conference on Civil and Architecture Engineering (Vol. 9, No. 9th International Conference on Civil and Architecture Engineering, pp. 1-12). Military Technical College.

3. Abdelalim, A. M. (2019). A novel diagnostic prognostic approach for rehabilitated RC structures based on integrated probabilistic deterioration models. International Journal of Decision Sciences, Risk and Management, 8(3), 119-134.

4. Abdelalim, A. M., & Abo. elsaud, Y. (2019). Integrating BIM based simulation technique for sustainable building design. In Project Management and BIM for Sustainable Modern Cities: Proceedings of the 2nd GeoMEast International Congress and Exhibition on Sustainable Civil Infrastructures, Egypt 2018 The Official International Congress of the Soil-Structure Interaction Group in Egypt (SSIGE) (pp. 209-238). Springer International Publishing.

5. Ali Mohamed, N., Mohammed Abdel-Alim, A., Hamdy Ghith, H., & Gamal Sherif, A. (2020). Assessment and prediction planning of RC structures using BIM technology. Engineering Research Journal, 167, 394-403.

6. Abdelalim, A. M., & Said, S. O. M. (2021). Dynamic labor tracking system in construction project using bim technology. Int. J. Civ. Struct. Eng. Res, 9(20).

7. Shehab, A., & Abdelalim, A. M. Utilization BIM for Integrating Cost Estimation and Cost Control Using BIM in Construction Projects.2023.

8. Shawky, K. A., Abdelalim, A. M., & Sherif, A. G. (2024). Standardization of BIM Execution Plans (BEP’s) for Mega Construction Projects: A Comparative and Scientometric Study. Trans. Mach. Learn. Artif. Intell, 12(1), 103-129.

9. Abdelkhalek, S., & Zayed, T. (2020). Comprehensive inspection system for concrete bridge deck application: Current situation and future needs. Journal of Performance of Constructed Facilities, 34(5), 03120001.

10. Morgenthal, G., Hallermann, N., Kersten, J., Taraben, J., Debus, P., Helmrich, M., & Rodehorst, V. (2019). Framework for automated UAS-based structural condition assessment of bridges. Automation in Construction, 97, 77-95.

11. Kruachottikul, P., Cooharojananone, N., Phanomchoeng, G., Chavarnakul, T., Kovitanggoon, K., Trakulwaranont, D., & Atchariyachanvanich, K. (2019, October). Bridge sub structure defect inspection assistance by using deep learning. In 2019 IEEE 10th International Conference on Awareness Science and Technology (iCAST) (pp. 1-6). IEEE.

12. Dung, C. V. (2019). Autonomous concrete crack detection using deep fully convolutional neural network. Automation in Construction, 99, 52-58.

13. Mohammed Abdelkader, E. (2022). On the hybridization of pre-trained deep learning and differential evolution algorithms for semantic crack detection and recognition in ensemble of infrastructures. Smart and Sustainable Built Environment, 11(3), 740-764.

14. Chanda, S., Bu, G., Guan, H., Jo, J., Pal, U., Loo, Y. C., & Blumenstein, M. (2014). Automatic bridge crack detection–a texture analysis-based approach. In Artificial Neural Networks in Pattern Recognition: 6th IAPR TC 3 International Workshop, ANNPR 2014, Montreal, QC, Canada, October 6-8, 2014. Proceedings 6 (pp. 193-203). Springer International Publishing.

15. Cha, Y. J., Choi, W., & Büyüköztürk, O. (2017). Deep learningâ?based crack damage detection using convolutional neural networks. Computerâ?Aided Civil and Infrastructure Engineering, 32(5), 361-378.

16. Agdas, D., Rice, J. A., Martinez, J. R., & Lasa, I. R. (2016). Comparison of visual inspection and structural-health monitoring as bridge condition assessment methods. Journal of Performance of Constructed Facilities, 30(3), 04015049.

17. Abdelkader, E. M., Moselhi, O., Marzouk, M., & Zayed, T. (2020). Evaluation of spalling in bridges using machine vision method. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction (Vol. 37, pp. 1136-1143). IAARC Publications.

18. Mohammed Abdelkader, E., Moselhi, O., Marzouk, M., & Zayed, T. (2021). Hybrid Elman neural network and an invasive weed optimization method for bridge defect recognition. Transportation Research Record, 2675(3), 167 199.

19. Jain, R., & Sharma, R. S. (2018, July). Predicting Severity of Cracks in Concrete using Fuzzy Logic. In 2018 International Conference on Recent Innovations in Electrical, Electronics & Communication Engineering (ICRIEECE) (pp. 2976 2976). IEEE.

20. Mohan, A., & Poobal, S. (2018). Crack detection using image processing: A critical review and analysis. alexandria engineering journal, 57(2), 787-798.

21. Dorafshan, S., Thomas, R. J., & Maguire, M. (2018). Comparison of deep convolutional neural networks and edge detectors for image-based crack detection in concrete. Construction and Building Materials, 186, 1031-1045.

22. Moon, H. G., & Kim, J. H. (2011). Intelligent crack detecting algorithm on the concrete crack image using neural network. Proceedings of the 28th ISARC, 2011, 1461-1467.

23. Tong, X., Guo, J., Ling, Y., & Yin, Z. (2011, October). A new image-based method for concrete bridge bottom crack detection. In 2011 international conference on image analysis and signal processing (pp. 568-571). IEEE.

24. Zou, Q., Cao, Y., Li, Q., Mao, Q., & Wang, S. (2012). CrackTree: Automatic crack detection from pavement images. Pattern Recognition Letters, 33(3), 227-238.

25. Lattanzi, D., & Miller, G. R. (2014). Robust automated concrete damage detection algorithms for field applications. Journal of Computing in Civil Engineering, 28(2), 253-262.

26. Adhikari, R. S., Moselhi, O., & Bagchi, A. (2014). Image based retrieval of concrete crack properties for bridge inspection. Automation in construction, 39, 180-194.

27. Chen, Y., Mei, T., Wang, X., & Li, F. (2016, July). A bridge crack image detection and classification method based on climbing robot. In 2016 35th Chinese Control Conference (CCC) (pp. 4037-4042). IEEE.

28. Talab, A. M. A., Huang, Z., Xi, F., & HaiMing, L. (2016). Detection crack in image using Otsu method and multiple f iltering in image processing techniques. Optik, 127(3), 1030 1033.

29. Noh, Y., Koo, D., Kang, Y. M., Park, D., & Lee, D. (2017, May). Automatic crack detection on concrete images using segmentation via fuzzy C-means clustering. In 2017 International conference on applied system innovation (ICASI) (pp. 877-880). IEEE.

30. Safaei, N., Smadi, O., Masoud, A., & Safaei, B. (2022). An automatic image processing algorithm based on crack pixel density for pavement crack detection and classification. International Journal of Pavement Research and Technology, 15(1), 159-172.

31. de León, G., Fiorentini, N., Leandri, P., & Losa, M. (2023). A new region-based minimal path selection algorithm for crack detection and ground truth labeling exploiting Gabor filters. Remote Sensing, 15(11), 2722.

32. Dow, H., Perry, M., McAlorum, J., Pennada, S., & Dobie, G. (2023). Skeleton-based noise removal algorithm for binary concrete crack image segmentation. Automation in Construction, 151, 104867.

33. Li, Y., Zhao, W., Zhang, X., & Zhou, Q. (2018). A two stage crack detection method for concrete bridges using Convolutional Neural Networks. IEICE TRANSACTIONS on Information and Systems, 101(12), 3249-3252.

34. Mohtasham Khani, M., Vahidnia, S., Ghasemzadeh, L., Ozturk, Y. E., Yuvalaklioglu, M., Akin, S., & Ure, N. K. (2020). Deep-learning-based crack detection with applications for the structural health monitoring of gas turbines. Structural Health Monitoring, 19(5), 1440-1452.

35. Modarres, C., Astorga, N., Droguett, E. L., & Meruane, V. (2018). Convolutional neural networks for automated damage recognition and damage type identification. Structural Control and Health Monitoring, 25(10), e2230.

36. Zhu, J., Zhang, C., Qi, H., & Lu, Z. (2020). Vision-based defects detection for bridges using transfer learning and convolutional neural networks. Structure and Infrastructure Engineering, 16(7), 1037-1049.

37. Li, G., Liu, Q., Zhao, S., Qiao, W., & Ren, X. (2020). Automatic crack recognition for concrete bridges using a fully convolutional neural network and naive Bayes data fusion based on a visual detection system. Measurement Science and Technology, 31(7), 075403.

38. Meng, Q., Yang, J., Zhang, Y., Yang, Y., Song, J., & Wang, J. (2023). A Robot System for Rapid and Intelligent Bridge Damage Inspection Based on Deep-Learning Algorithms. Journal of Performance of Constructed Facilities, 37(6), 04023052.

39. Chen, A. (2023). Analysis of bridge foundation pile detection based on convolutional neural network model. Applied Mathematics and Nonlinear Sciences, 8(2), 2085-2094.

40. Yu, H. (2023, June). Research on Bridge Condition Monitoring Based on Image Processing Technology and Bridge Crack Detection Algorithm. In 2023 2nd International Conference on 3D Immersion, Interaction and Multi-sensory Experiences (ICDIIME) (pp. 412-416). IEEE.

41. Zhu, J., & Song, J. (2020). An intelligent classification model for surface defects on cement concrete bridges. Applied sciences, 10(3), 972.

42. Kim, I. H., Jeon, H., Baek, S. C., Hong, W. H., & Jung, H. J. (2018). Application of crack identification techniques for an aging concrete bridge inspection using an unmanned aerial vehicle. Sensors, 18(6), 1881.

43. Xu, H., Su, X., Wang, Y., Cai, H., Cui, K., & Chen, X. (2019). Automatic bridge crack detection using a convolutional neural network. Applied Sciences, 9(14), 2867.

44. Dorafshan, S., Thomas, R. J., Coopmans, C., & Maguire, M. (2018, June). Deep learning neural networks for sUAS assisted structural inspections: Feasibility and application. In 2018 international conference on unmanned aircraft systems (ICUAS) (pp. 874-882). IEEE.

45. Zhao, X., Li, S., Su, H., Zhou, L., & Loh, K. J. (2018, September). Image-based comprehensive maintenance and inspection method for bridges using deep learning. In Smart Materials, Adaptive Structures and Intelligent Systems (Vol. 51951, p. V002T05A017). American Society of Mechanical Engineers.

46. SÅ?oÅ?ski, M. (2019). A comparison of deep convolutional neural networks for image-based detection of concrete surface cracks. Computer assisted methods in Engineering and Science, 26(2), 105-112.

47. Hüthwohl, P., Lu, R., & Brilakis, I. (2019). Multi-classifier for reinforced concrete bridge defects. Automation in Construction, 105, 102824.

48. Zhu, J., & Song, J. (2020). Weakly supervised network based intelligent identification of cracks in asphalt concrete bridge deck. Alexandria Engineering Journal, 59(3), 1307-1317.

49. Deng, W., Mou, Y., Kashiwa, T., Escalera, S., Nagai, K., Nakayama, K., ... & Prendinger, H. (2020). Vision based pixel-level bridge structural damage detection using a link ASPP network. Automation in Construction, 110, 102973.

50. Cardellicchio, A., Ruggieri, S., Nettis, A., Patruno, C., Uva, G., & Renò, V. (2022, May). Deep learning approaches for image-based detection and classification of structural defects in bridges. In International Conference on Image Analysis and Processing (pp. 269-279). Cham: Springer International Publishing.

51. Kruachottikul, P., Cooharojananone, N., Phanomchoeng, G., Chavarnakul, T., Kovitanggoon, K., & Trakulwaranont, D. (2021). Deep learning-based visual defect-inspection system for reinforced concrete bridge substructure: a case of Thailand’s department of highways. Journal of Civil Structural Health Monitoring, 11(4), 949-965.

52. Shamila Ebenezer, A., Deepa Kanmani, S., Sheela, V., Ramalakshmi, K., Chandran, V., Sumithra, M. G., ... & Murugesan, B. (2021). Identification of Civil Infrastructure Damage Using Ensemble Transfer Learning Model. Advances in Civil Engineering, 2021(1), 5589688.

53. Zoubir, H., Rguig, M., El Aroussi, M., Chehri, A., Saadane, R., & Jeon, G. (2022). Concrete bridge defects identification and localization based on classification deep convolutional neural networks and transfer learning. Remote sensing, 14(19), 4882.

54. Li, R., Yu, J., Li, F., Yang, R., Wang, Y., & Peng, Z. (2023). Automatic bridge crack detection using Unmanned aerial vehicle and Faster R-CNN. Construction and Building Materials, 362, 129659.

55. Zhu, Z., German, S., & Brilakis, I. (2011). Visual retrieval of concrete crack properties for automated post-earthquake structural safety evaluation. Automation in Construction, 20(7), 874-883.

56. Ge, B. Z., Luo, Q. J., Ma, B., Wei, Y. J., Chen, B., & Jiang, S. Z. (2013). The algorithm to measure crack width with incircle. Advanced Materials Research, 684, 481-485.

57. German, S., Brilakis, I., & DesRoches, R. (2012). Rapid entropy-based detection and properties measurement of concrete spalling with machine vision for post-earthquake safety assessments. Advanced Engineering Informatics, 26(4), 846-858.

58. Ong, J. C., Ismadi, M. Z. P., & Wang, X. (2022). A hybrid method for pavement crack width measurement. Measurement, 197, 111260.

59. Abdelalim, A.M., Nahla Ali Mohamed fahmy, Hatem Hamdy Ghith, Alaa Gamal sheriff (2020). Condition Assessment and Deterioration Prediction of RC Structures, International Journal of Civil and Structural Engineering Research, 8(1), 173-181.

60. Yu, L., He, S., Liu, X., Jiang, S., & Xiang, S. (2022). Intelligent Crack Detection and Quantification in the Concrete Bridge: A Deep Learningâ?Assisted Image Processing Approach. Advances in Civil Engineering, 2022(1), 1813821.

61. Bae, H., & An, Y. K. (2023). Computer vision-based statistical crack quantification for concrete structures. Measurement, 211, 112632.

62. Kao, S. P., Chang, Y. C., & Wang, F. L. (2023). Combining the YOLOv4 deep learning model with UAV imagery processing technology in the extraction and quantization of cracks in bridges. Sensors, 23(5), 2572.

63. Tran, T. S., Nguyen, S. D., Lee, H. J., & Tran, V. P. (2023). Advanced crack detection and segmentation on bridge decks using deep learning. Construction and Building Materials, 400, 132839.

64. Gopalakrishnan, K., Khaitan, S. K., Choudhary, A., & Agrawal, A. (2017). Deep convolutional neural networks with transfer learning for computer vision-based data-driven pavement distress detection. Construction and building materials, 157, 322-330.

65. Yang, Q., Shi, W., Chen, J., & Lin, W. (2020). Deep convolution neural network-based transfer learning method for civil infrastructure crack detection. Automation in Construction, 116, 103199.

66. Hiasa, S., Karaaslan, E., Shattenkirk, W., Mildner, C., & Catbas, F. N. (2018, April). Bridge inspection and condition assessment using image-based technologies with UAVs. In Structures Congress 2018 (pp. 217-228). Reston, VA: American Society of Civil Engineers

67. Elbehairy, H. (2007). Bridge management system with integrated life cycle cost optimization.